Understanding Greenhouse Heating Needs

Stable greenhouse heating is critical for plant health and productivity. Plants require specific temperature thresholds for optimal growth. Deviations as small as 2–3°C can significantly slow metabolic processes. Effective thermoregulation ensures plants remain within their ideal plant temperature range, promoting vigorous development.

Heat loss in greenhouses occurs primarily through conduction and infiltration. This necessitates consistent heat sources to maintain a controlled microclimate. For most gardeners, understanding greenhouse microclimate control is paramount. A 4°C nightly temperature drop can result in up to 15% lower yields in sensitive crops, highlighting the impact of temperature fluctuations. Current best practices emphasize steady night-time temperatures to reduce crop stress and maximize overall yield, according to agricultural experts at UMass Extension.

How Electric Heaters Work in Greenhouses

Electric greenhouse heaters offer a straightforward yet effective method for maintaining optimal growing temperatures. These units employ resistive heating elements, converting electrical energy directly into thermal energy. According to University of New Hampshire Extension, this conversion process achieves near 100% efficiency at the point of use, minimizing wasted energy. This makes them a practical choice for supplemental or primary heating needs.

Modern safe greenhouse heaters incorporate advanced features for precise climate regulation. Thermostatic control is standard, allowing users to set and maintain desired temperatures with minimal intervention. As a direct result, many models include features like automatic shut-off and overheat protection, ensuring reliable and safe operation. The absence of on-site combustion means zero-carbon at point of use, avoiding direct CO or water vapor emissions within the greenhouse airspace. This clean operation is a significant benefit for sensitive plant life and overall air quality.

In practical terms, the simplicity of resistive heating greenhouse applications translates to ease of installation and use. Often designed as plug-and-play safety units, they require minimal setup. Electric greenhouse heaters deliver up to 99% conversion efficiency from power input to heat, a measurable metric underscoring their performance. Current best practices emphasize their utility for localized or smaller-scale environments where consistent, controllable heat is paramount.

Propane Heaters — Functionality and Features

Propane greenhouse heaters harness controlled combustion to generate significant heat. This process converts propane into thermal energy, often providing high BTU output suitable for larger spaces. Portable models offer flexibility, especially for off-grid applications, but demand diligent attention to fuel management and oxygen monitoring.

The combustion process inherently produces CO2 and water vapor. While moderate CO2 enrichment can benefit plant growth, insufficient ventilation poses a significant risk of carbon monoxide buildup. For optimal performance and safety, well-vented propane heaters can achieve up to 92% combustion efficiency, ensuring more heat and less wasted fuel.

By comparison with electric alternatives, propane heaters deliver powerful, rapid heating. However, they require careful consideration of ventilation needs. Modern greenhouse designs often integrate vented models to manage byproducts, ensuring a safer environment for both plants and growers.

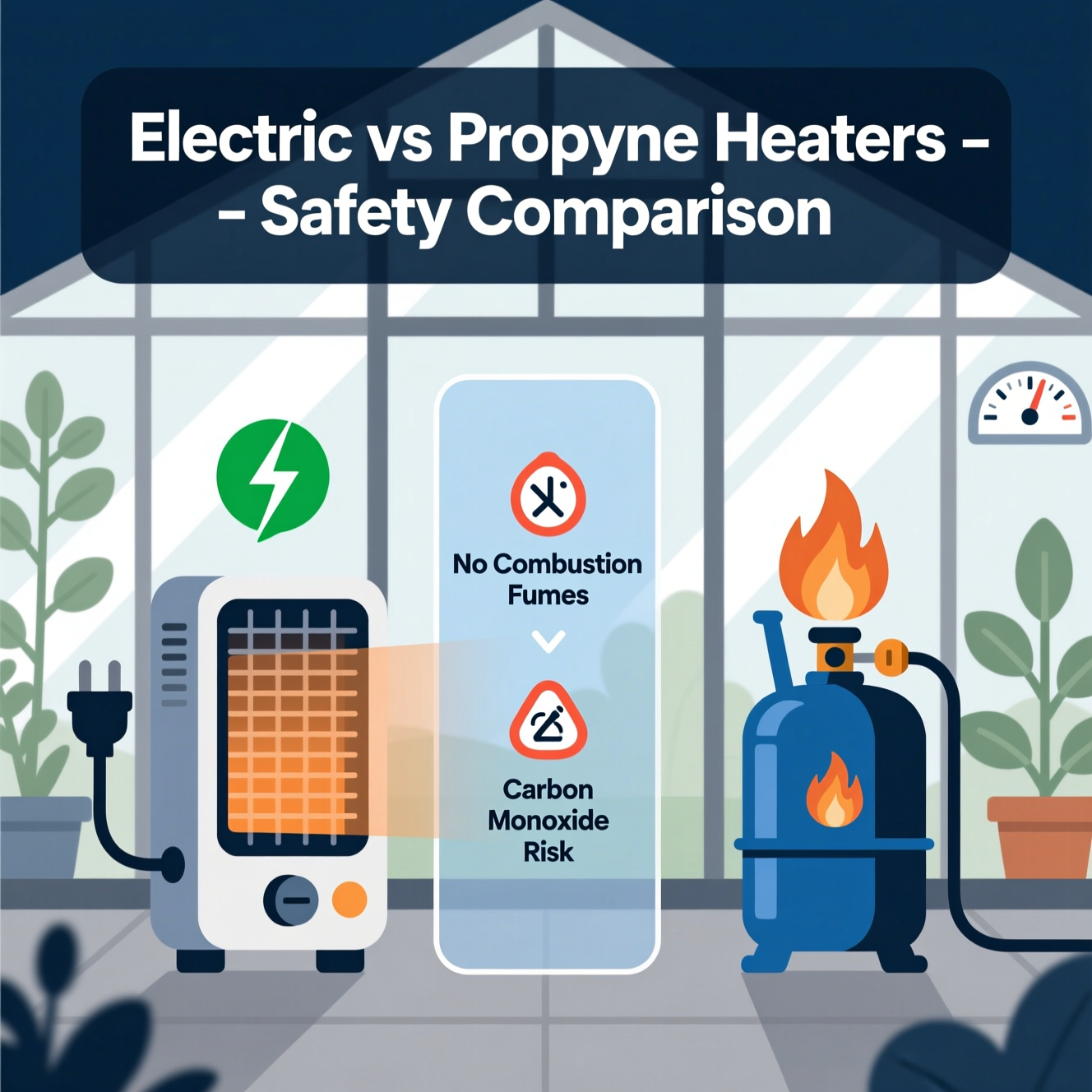

Comparing Safety — Electric vs Propane

Evaluating greenhouse heater safety involves understanding distinct risks. Electric heaters do not produce carbon monoxide (CO) or combustion gases. This significantly reduces air quality concerns, especially in sealed greenhouse environments. Modern propane heaters incorporate safety features like oxygen depletion and tip-over shutoff sensors. However, they inherently require proper venting and reliable CO alarms for safe operation. For most gardeners, this distinction is paramount for greenhouse CO risk management.

Unvented propane heaters can elevate indoor CO concentrations past safe thresholds in as little as 30 minutes, according to recent studies. In contrast, electric heaters, while not producing CO, pose different safety considerations. Exposure to water can cause short-circuiting; therefore, employing IP-rated models is strongly recommended for humid greenhouse conditions. This ensures greater electrical safety. Recent research emphasizes the importance of selecting the right greenhouse heater safety features to match environmental needs.

Environmental Impact Considerations

Moreover, understanding greenhouse heater emissions is vital for sustainable greenhouse heating. Electric heaters can offer lower environmental impact if powered by renewable electricity sources. In contrast, propane is derived directly from fossil fuels, involving significant extraction and processing.

On-site propane combustion releases direct CO2 and water vapor. Electric systems, however, produce indirect emissions tied to the energy grid’s sourcing. Electric greenhouse heating from solar or wind can reduce operational greenhouse gas emissions by over 60% versus propane. Lifecycle analyses, such as those detailed by the EPA, show electric systems narrow the emissions gap as renewables become prevalent, offering a clearer path for sustainable practices.

Cost Efficiency and Operating Expenses

Understanding greenhouse heater cost involves evaluating both initial investments and ongoing operational expenses. Electric heaters typically present lower upfront costs. However, their long-term expense can escalate significantly in regions with high kWh rates. Conversely, liquid propane heating systems offer a viable alternative, especially in off-grid settings.

Propane heaters require consistent fuel deliveries and regular tank maintenance, adding to their operational burden. While liquid propane cost per BTU can be considerably lower, often up to 50% less in rural areas, these savings may be offset by other factors. Performing an energy audit is crucial for determining site-specific ROI, considering local energy prices and greenhouse insulation levels.

With over 15 years of hands-on experience in controlled-environment agriculture, Angelina leads our lab audits. Her focus is on bridging the gap between high-end agricultural tech and the home grower, ensuring every recommendation is backed by real-world data and yield performance.